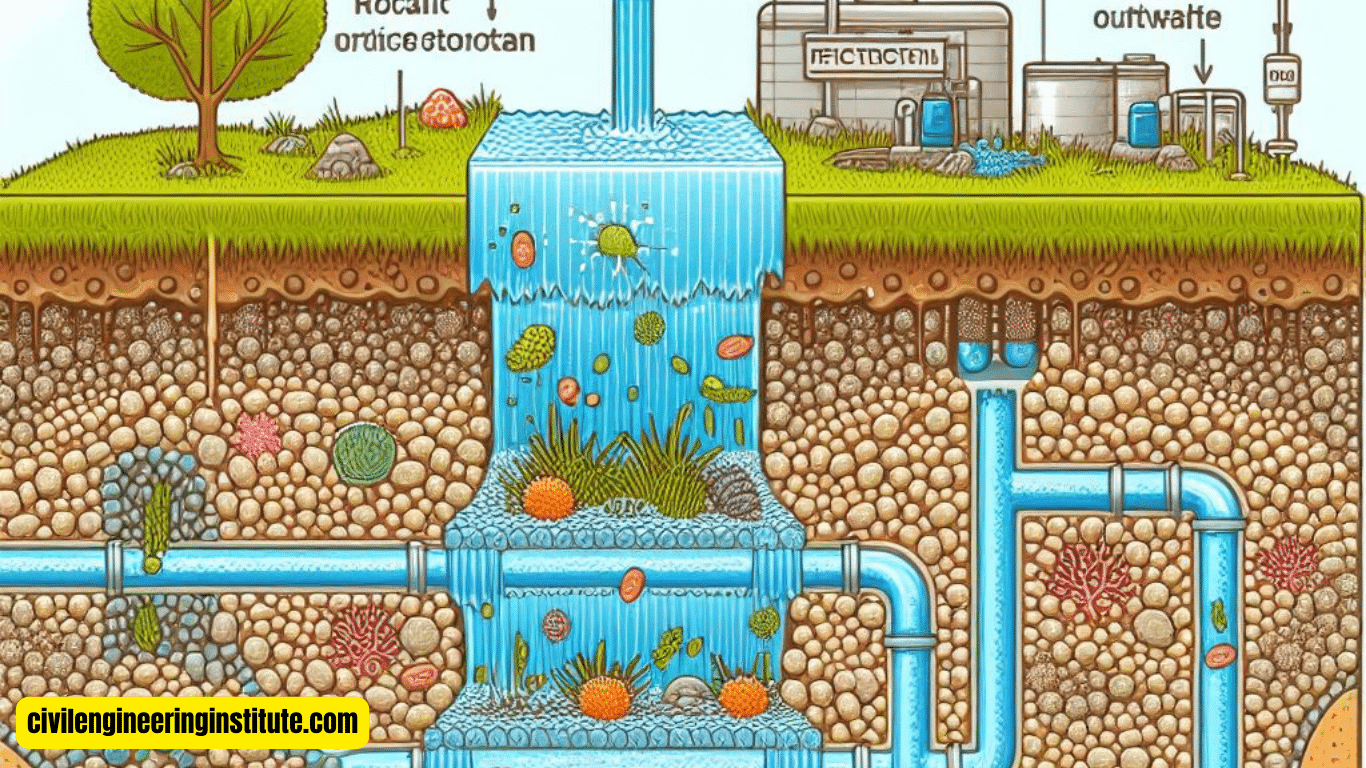

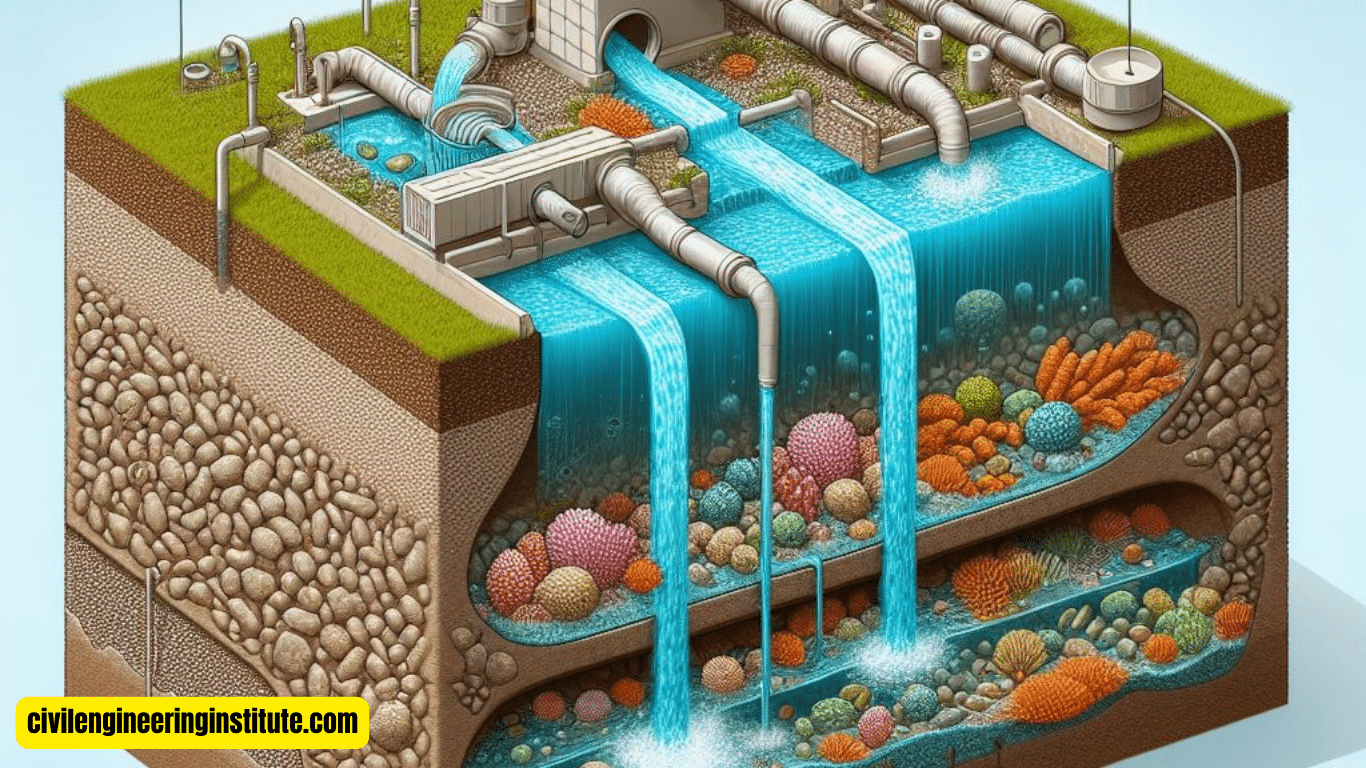

The trickling filter working principle is a fundamental concept in wastewater treatment, offering an efficient and eco-friendly solution to purify water. Simply put, a trickling filter consists of a bed of rocks, gravel, or synthetic media through which wastewater is passed. As the wastewater trickles over the surface of the media, beneficial bacteria and microorganisms attach themselves to the media and begin to consume organic matter and pollutants present in the water.

This biological process breaks down the contaminants, effectively purifying the wastewater. The trickling filter relies on aerobic conditions, meaning it requires oxygen to sustain the microbial activity. To ensure optimal performance, the trickling filter must maintain a balance between the flow rate of wastewater and the surface area of the media, allowing sufficient contact time for the microorganisms to treat the water effectively. Overall, the trickling filter working principle offers a cost-effective and environmentally friendly method for treating wastewater, making it a popular choice in wastewater treatment plants worldwide.

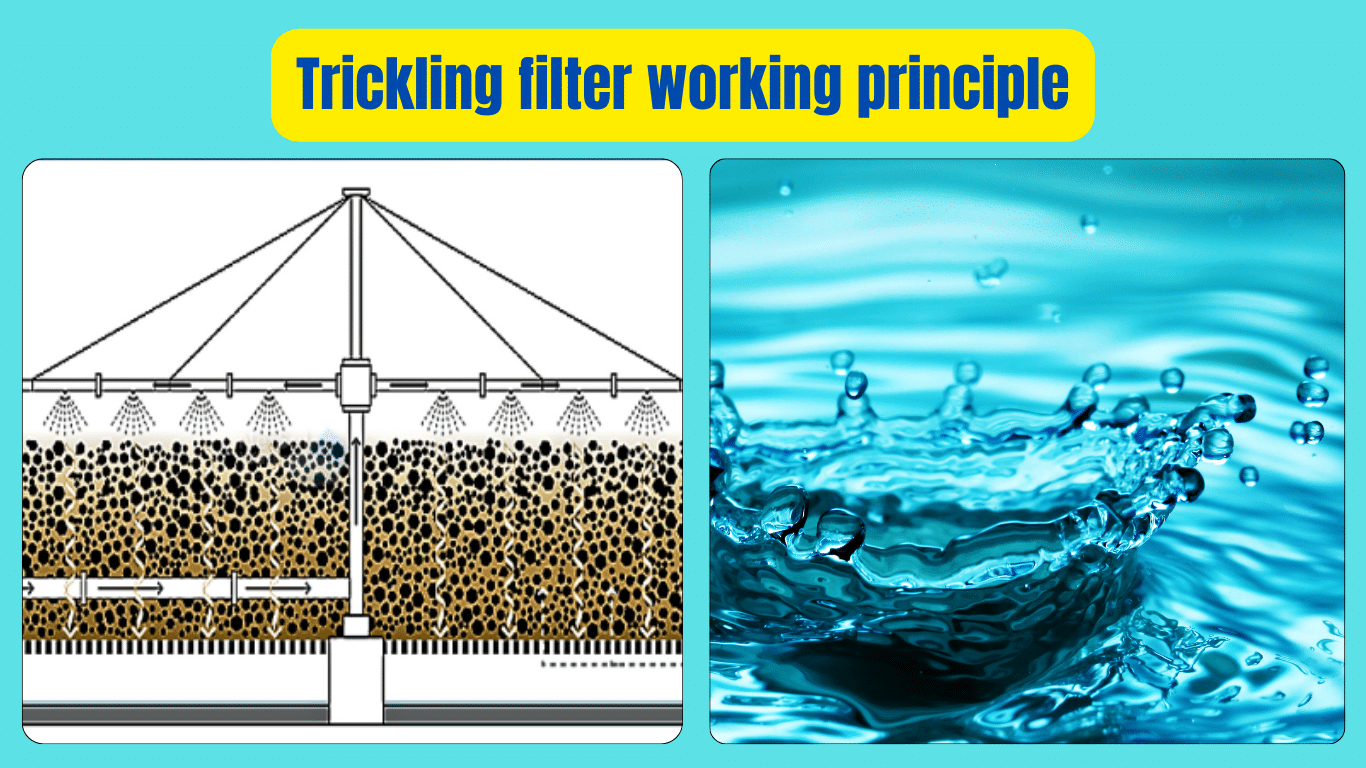

Trickling filter working principle

Trickling filters serve as one of the key components in wastewater treatment plants, providing an effective method for purifying water before it is discharged back into the environment. The working principle of trickling filters revolves around harnessing the power of beneficial bacteria and microorganisms to break down organic matter and contaminants present in wastewater. In this comprehensive guide, we will delve into the intricacies of the trickling filter working principle, exploring how it functions and its significance in wastewater treatment processes.

Understanding the Basics of Trickling Filters

At its core, a trickling filter consists of a bed of porous media, such as rocks, gravel, or synthetic materials, through which wastewater flows. As the wastewater trickles over the surface of the media, it comes into contact with a thin film of microbial biomass known as biofilm. This biofilm is comprised of diverse microbial communities, including bacteria, fungi, and protozoa, which attach themselves to the media and begin to metabolize and degrade organic compounds present in the wastewater.

The Biological Process Behind Trickling Filters

The effectiveness of trickling filters stems from the biological processes that occur within the biofilm. As wastewater flows over the media surface, organic matter and pollutants are absorbed into the biofilm, where they serve as a food source for the microorganisms. These microorganisms utilize oxygen from the air or from the flowing wastewater to carry out aerobic metabolism, breaking down complex organic compounds into simpler, less harmful substances such as carbon dioxide and water.

Key Components of Trickling Filters

Several key components contribute to the successful operation of trickling filters:

- Media Bed

- Distribution System

- Aeration

- Effluent Collection

Media Bed: The media bed provides a surface for the formation of biofilm and facilitates the contact between wastewater and microbial biomass.

Distribution System: A distribution system evenly distributes wastewater over the surface of the media bed, ensuring uniform contact and treatment.

Aeration: Adequate aeration is essential to maintain aerobic conditions within the trickling filter, providing oxygen to support microbial growth and activity.

Effluent Collection: Effluent collection channels or pipes collect treated wastewater that has passed through the trickling filter, ready for further treatment or discharge.

Optimizing the Performance of Trickling Filters

To ensure optimal performance, several factors must be considered when designing and operating trickling filters:

- Media Selection

- Hydraulic Loading Rate

- Temperature and pH

- Maintenance and Monitoring

Media Selection: The choice of media material and size influences the surface area available for biofilm formation and the porosity of the media bed, affecting the efficiency of organic matter removal.

Hydraulic Loading Rate: The hydraulic loading rate, or the rate at which wastewater flows over the media surface, must be carefully controlled to provide sufficient contact time for microbial treatment without causing clogging or hydraulic overloading.

Temperature and pH: Temperature and pH levels play a crucial role in microbial activity and metabolism within the trickling filter. Optimal temperature and pH ranges must be maintained to support microbial growth and enzymatic reactions.

Maintenance and Monitoring: Regular maintenance and monitoring of trickling filters are essential to ensure proper functioning and performance. This includes periodic inspection of media condition, distribution system integrity, and effluent quality.

Advantages of Trickling Filters

Trickling filters offer several advantages as a wastewater treatment technology:

- Cost-Effectiveness

- Energy Efficiency

- Robustness and Reliability

- Environmental Sustainability

Cost-Effectiveness: Trickling filters are relatively simple and cost-effective to construct and operate, making them suitable for small to medium-sized treatment plants.

Energy Efficiency: Unlike some treatment processes that require significant energy input for aeration or mixing, trickling filters rely on natural processes and gravity flow, minimizing energy consumption.

Robustness and Reliability: Trickling filters are robust and reliable, capable of effectively treating a wide range of wastewater types and fluctuations in flow and organic loading.

Environmental Sustainability: By harnessing natural biological processes, trickling filters offer an environmentally sustainable approach to wastewater treatment, minimizing the use of chemicals and energy-intensive treatment methods.

Challenges and Considerations

Despite their numerous advantages, trickling filters also face some challenges and considerations.

- Limited Nutrient Removal

- Seasonal Variability

- Potential Odor Issues

Limited Nutrient Removal: Trickling filters are primarily designed for organic matter removal and may not effectively remove nutrients such as nitrogen and phosphorus without additional treatment steps.

Seasonal Variability: Changes in temperature and flow rates can impact the performance of trickling filters, requiring adjustments to operating conditions or supplementary treatment measures.

Potential Odor Issues: In some cases, trickling filters may generate odors due to the accumulation of volatile organic compounds or hydrogen sulfide gas. Proper design and operation can help mitigate odor issues.

Some Key Points: Trickling filter working principle

How do trickling filters work?

Trickling filters work by harnessing the power of beneficial bacteria and microorganisms to purify wastewater. In a trickling filter, wastewater is evenly distributed over a bed of porous media, such as rocks or gravel. As the wastewater trickles down through the media, it comes into contact with a thin film of microbial biomass known as biofilm. This biofilm is made up of diverse microorganisms that attach themselves to the media surface. As the wastewater flows over the biofilm, the microorganisms metabolize and break down organic matter and contaminants present in the water, effectively treating the wastewater.

The Biological Principle of Trickling Filter

The biological principle behind trickling filters lies in the activity of the microorganisms within the biofilm. These microorganisms, including bacteria, fungi, and protozoa, utilize oxygen from the air or the flowing wastewater to carry out aerobic metabolism. During this process, they consume organic matter and pollutants in the wastewater, transforming them into simpler, less harmful substances such as carbon dioxide and water. The biofilm provides a conducive environment for microbial growth and activity, allowing for efficient treatment of the wastewater.

Primary Operation in Trickling Filter

The primary operation in a trickling filter involves the interaction between wastewater and the microbial biofilm on the media surface. The microorganisms in the biofilm absorb and metabolize organic matter and contaminants as wastewater flows over them, purifying the water as a result. The continuous flow of oxygen from the air or the wastewater supports this biological process by maintaining aerobic conditions inside the trickling filter.

Factors Affecting Trickling Filter Performance

Several factors influence the performance of trickling filters, including:

- Media Characteristics

- Hydraulic Loading Rate

- Temperature and pH

- Nutrient Availability

Media Characteristics: The type, size, and porosity of the media affect the surface area available for biofilm formation and the hydraulic conductivity of the filter.

Hydraulic Loading Rate: The rate at which wastewater flows over the media surface impacts the contact time between wastewater and biofilm, influencing treatment efficiency.

Temperature and pH: Optimal temperature and pH levels are essential for microbial activity within the trickling filter, affecting the rate of organic matter degradation.

Nutrient Availability: Adequate nutrients such as nitrogen and phosphorus are necessary to support microbial growth and metabolism within the trickling filter.

Types of Trickling Filters

Trickling filters can be classified based on their hydraulic loading rate into low-rate and high-rate trickling filters. Low-rate trickling filters typically operate at hydraulic loading rates of less than 200 liters per square meter per hour, while high-rate trickling filters operate at higher loading rates, often exceeding 200 liters per square meter per hour.

Bacteria Used in Trickling Filters

Various types of bacteria, including heterotrophic and autotrophic bacteria, are used in trickling filters. Heterotrophic bacteria metabolize organic matter, while autotrophic bacteria utilize inorganic compounds such as ammonia for energy metabolism. Together, these bacteria play a vital role in the biological treatment of wastewater within trickling filters.

Particle Size in Trickling Filters

The size of particles used in trickling filters varies depending on the specific design and application. Typically, the media particles range in size from a few millimeters to several centimeters, providing a porous structure that supports the attachment and growth of microbial biofilm.

Detention Time in Trickling Filters

The detention time, or the average time that wastewater spends in the trickling filter, is an important parameter that influences treatment efficiency. Longer detention times allow for more extensive contact between wastewater and biofilm, enhancing treatment effectiveness.

Choosing a Biological Wastewater Treatment System

Trickling filters are a popular choice for biological wastewater treatment due to their simplicity, reliability, and cost-effectiveness. However, other biological treatment systems, such as activated sludge processes and constructed wetlands, may also be suitable depending on specific site conditions and treatment objectives. It’s essential to consider factors such as space availability, effluent quality requirements, and operational preferences when selecting a wastewater treatment system.

Conclusion

In conclusion, the trickling filter working principle exemplifies the ingenuity of harnessing natural processes to address complex environmental challenges. By leveraging the microbial communities within biofilm, trickling filters offer an efficient, cost-effective, and environmentally sustainable solution for purifying wastewater. As the demand for wastewater treatment continues to grow, trickling filters remain a vital tool in ensuring the health and sustainability of our water resources, underscoring their significance in modern wastewater treatment practices.

FAQs

How does a trickling filter work?

A trickling filter works by passing wastewater over a bed of media where beneficial bacteria and microorganisms attach and break down organic matter, purifying the water.

What is the biological principle behind trickling filters?

The biological principle involves microorganisms in a biofilm metabolizing organic matter in the wastewater and converting it into simpler, less harmful substances.

What is the primary operation of a trickling filter?

The primary operation involves wastewater flowing over the media surface, allowing microorganisms to treat the water by consuming organic matter and contaminants.

What is the flow rate of a trickling filter?

The flow rate varies but is controlled to ensure sufficient contact time between wastewater and the microbial biofilm for effective treatment.

Can you give an example of a trickling filter?

An example of a trickling filter is a bed of rocks or synthetic media through which wastewater flows in a wastewater treatment plant.

What factors affect trickling filter performance?

Factors such as media characteristics, hydraulic loading rate, temperature, pH, and nutrient availability influence trickling filter performance.

How are trickling filters classified?

Trickling filters are classified based on hydraulic loading rate into low-rate and high-rate trickling filters, depending on the flow rate of wastewater.

Which type of bacteria are used in trickling filters?

Various bacteria, including heterotrophic and autotrophic bacteria, are used in trickling filters to metabolize organic matter and contaminants.

What is a low-rate trickling filter?

A low-rate trickling filter operates at lower hydraulic loading rates, typically less than 200 liters per square meter per hour, for effective treatment.

What is a high-rate trickling filter?

A high-rate trickling filter operates at higher hydraulic loading rates, often exceeding 200 liters per square meter per hour, while maintaining treatment efficiency.