Soil bearing capacity test equipment is used to determine how much weight the soil can support before it starts to collapse or fail. This equipment is crucial for engineers and builders when designing structures like buildings, bridges, or roads. It helps them understand the strength of the soil and ensures that the foundations of these structures are stable and safe.

The equipment typically includes tools like penetrometers, plate load testers, and cone penetrometer tests, which measure the resistance of the soil to penetration or compression. By conducting these tests, professionals can make informed decisions about construction projects, preventing potential disasters and ensuring the safety of people and property.

Understanding Soil Bearing Capacity Test Equipment

Soil bearing capacity is a crucial factor in construction projects, determining the ability of the soil to support the weight of a structure. To assess this, engineers employ specialized equipment designed for soil bearing capacity tests. This equipment plays a vital role in ensuring the safety and stability of buildings, bridges, roads, and other infrastructure projects. In this article, we delve into the various types of soil bearing capacity test equipment, their functions, and significance in construction projects.

Types of Soil Bearing Capacity Test Equipment

There are several types of equipment used for conducting soil bearing capacity tests, each serving specific purposes and varying in complexity.

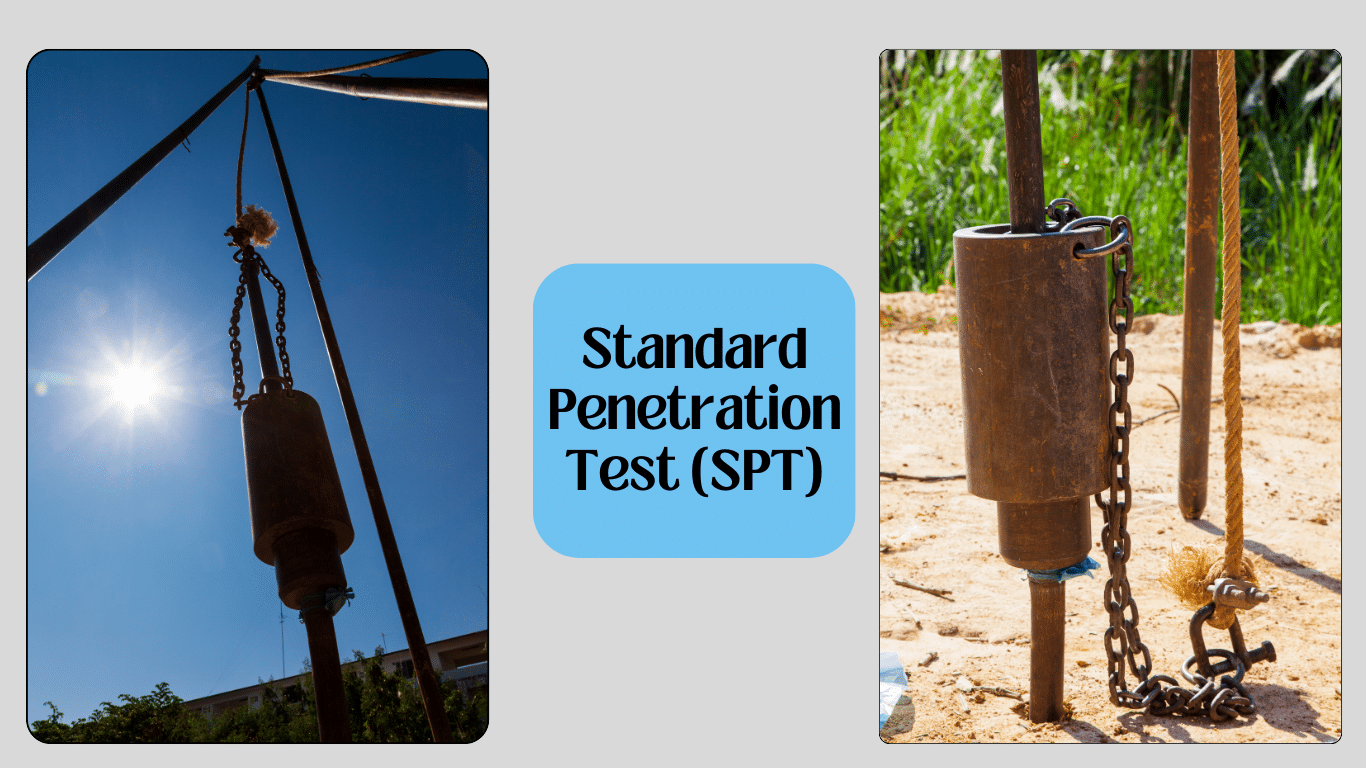

- Standard Penetration Test (SPT) Equipment

- Cone Penetration Test (CPT) Equipment

- Plate Load Test Equipment

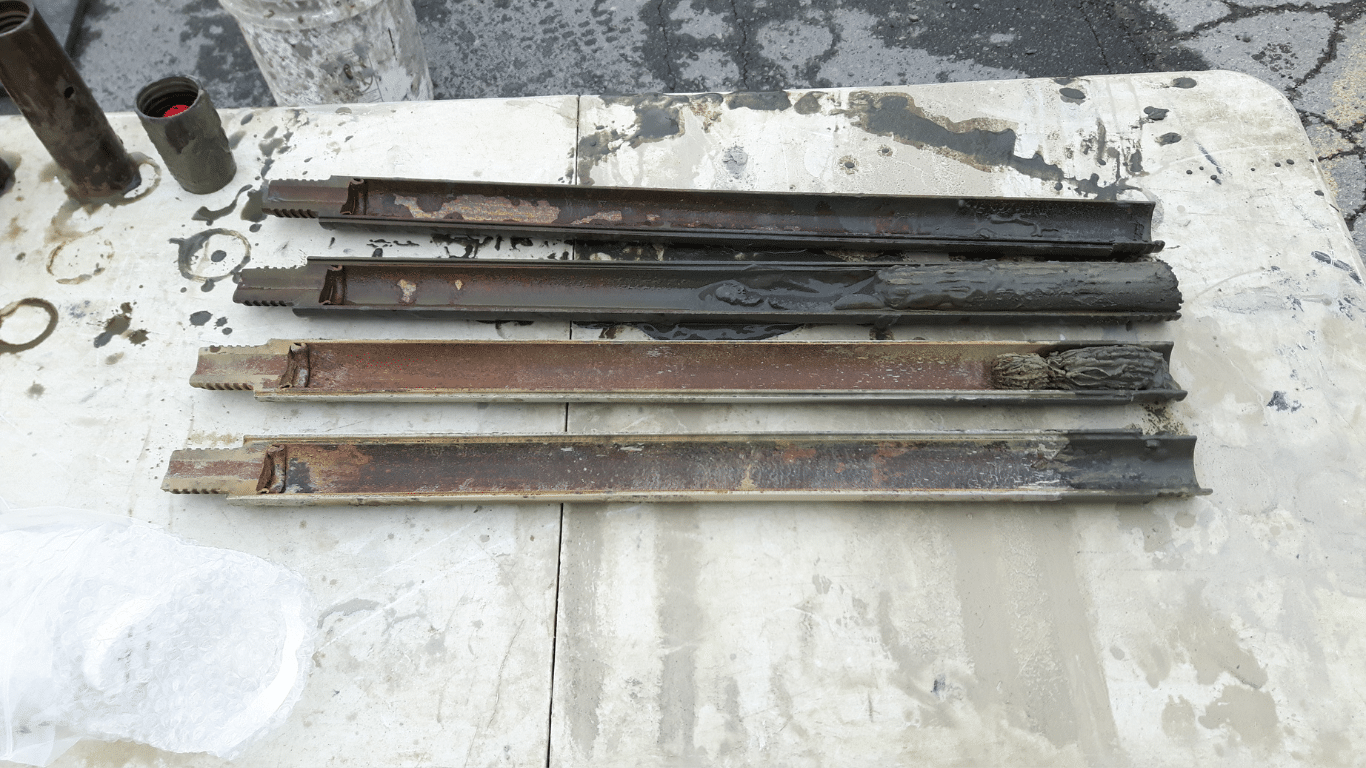

Standard Penetration Test (SPT) Equipment: SPT equipment is commonly used to measure the resistance of soil layers to penetration. It consists of a drilling rig, drill rods, a sampling spoon, and a hammer. During the test, the drill rig is driven into the ground, and the number of blows required to penetrate the soil at various depths is recorded. This data helps engineers determine soil strength and bearing capacity.

Cone Penetration Test (CPT) Equipment: CPT equipment consists of a cone-shaped penetrometer attached to a rod. It is pushed into the ground at a constant rate, measuring the resistance encountered as it penetrates the soil. The data collected from CPT tests provides valuable information about soil properties, including bearing capacity, shear strength, and soil stratification.

Plate Load Test Equipment: Plate load test equipment is used to directly measure the bearing capacity of soil beneath a specific area. It involves placing a steel plate of known dimensions and weight on the ground surface and applying a gradually increasing load. Instruments such as hydraulic jacks, dial gauges, and load cells are used to measure the settlement of the plate and calculate the bearing capacity of the soil.

Functions of Soil Bearing Capacity Test Equipment

Soil bearing capacity test equipment serves several important functions in the field of geotechnical engineering and construction:

- Assessment of Soil Strength

- Evaluation of Site Suitability

- Risk Mitigation

- Optimization of Foundation Design

Assessment of Soil Strength: By conducting bearing capacity tests, engineers can assess the strength and stability of soil, which is essential for determining suitable foundation designs.

Evaluation of Site Suitability: Soil bearing capacity tests help determine the suitability of a site for construction projects. Sites with poor soil bearing capacity may require special foundation techniques or soil improvement methods.

Risk Mitigation: Understanding the bearing capacity of soil helps mitigate the risk of foundation failure or settlement, which could lead to costly repairs and compromises in structural integrity.

Optimization of Foundation Design: Accurate data obtained from soil bearing capacity tests allows engineers to optimize foundation designs, ensuring they are both cost-effective and capable of supporting the intended loads.

Significance of Soil Bearing Capacity Test Equipment

The significance of soil bearing capacity test equipment cannot be overstated in the construction industry. Here are some key reasons why it is essential:

- Safety

- Cost-Effectiveness

- Compliance with Regulations

- Sustainability

Safety: Ensuring the stability and integrity of structures is paramount for the safety of occupants and the public. Soil bearing capacity tests help identify potential risks and ensure that appropriate measures are taken to mitigate them.

Cost-Effectiveness: Conducting soil bearing capacity tests helps prevent costly mistakes during construction. By accurately assessing soil properties, engineers can avoid overdesigning foundations or encountering unexpected issues that require expensive remediation.

Compliance with Regulations: Many building codes and regulations require thorough soil testing to ensure compliance with safety standards. Soil bearing capacity test equipment facilitates compliance by providing the necessary data to demonstrate the structural adequacy of foundations.

Sustainability: By optimizing foundation designs based on accurate soil data, engineers can reduce the environmental impact of construction projects. This includes minimizing excavation and material usage, as well as avoiding unnecessary disturbance to natural habitats.

Testing Soil Bearing Capacity: A Simple Guide

Testing soil bearing capacity is crucial in construction projects to ensure the stability and safety of structures. One common method is the plate bearing test, which involves using specialized equipment to determine the load-bearing capacity of soil.

Understanding Plate Bearing Test Equipment

Plate bearing test equipment consists of a steel plate of known dimensions and weight, hydraulic jacks, dial gauges, and load cells. The steel plate is placed on the ground surface, and a gradually increasing load is applied using the hydraulic jacks. Instruments such as dial gauges and load cells measure the settlement of the plate, providing data to calculate the bearing capacity of the soil.

Apparatus Used in Plate Load Test

The apparatus used in a plate load test includes hydraulic jacks for applying the load, dial gauges or LVDT (Linear Variable Differential Transformer) for measuring settlement, load cells for measuring applied load, and a steel plate of specified dimensions.

Calculating Bearing Capacity from Plate Load Test

To calculate the bearing capacity of soil from a plate load test, the settlement of the plate under a known load is measured. This data is then used to determine the pressure applied to the soil and its corresponding bearing capacity.

Methods of SBC Testing

There are various methods of soil bearing capacity (SBC) testing, including plate load tests, cone penetration tests (CPT), and standard penetration tests (SPT). Each method offers unique insights into soil properties and bearing capacity.

Different Types of Bearing Tests

Apart from the plate load test, other types of bearing tests include the California Bearing Ratio (CBR) test, cone penetration test (CPT), and standard penetration test (SPT). Each test has its own set of equipment and procedures for assessing soil bearing capacity.

Difference Between CBR and Plate Bearing Test

The main difference between the California Bearing Ratio (CBR) test and the plate bearing test lies in their objectives and methodologies. While the plate bearing test directly measures the load-bearing capacity of soil beneath a specific area, the CBR test evaluates the strength of a soil sample compacted under standardized conditions.

Size of Plate Used in Plate Load Test

The size of the plate used in a plate load test varies depending on factors such as the expected bearing capacity of the soil and the size of the structure being constructed. Typically, plates range from 300 mm to 750 mm in diameter.

Maximum Size of Plate for Plate Load Test

The maximum size of the plate used in a plate load test is determined by the size of the area being tested and the capacity of the testing equipment. Larger plates may be used for testing larger areas or soils with higher bearing capacities.

Conclusion

Soil bearing capacity test equipment plays a vital role in ensuring the safety, stability, and sustainability of construction projects. By accurately assessing soil properties, engineers can make informed decisions about foundation design, risk mitigation, and compliance with regulations. Investing in high-quality soil bearing capacity test equipment is essential for achieving successful outcomes in construction endeavors.

FAQs

What is soil bearing capacity testing?

Soil bearing capacity testing is a process used in construction to measure the ability of soil to support the weight of structures like buildings and roads.

Why is soil bearing capacity testing important?

It’s important because it helps ensure the safety and stability of structures by determining if the soil can handle the weight placed on it.

What is a plate bearing test?

A plate bearing test involves placing a steel plate on the ground and gradually applying load to measure how much the soil can support.

What equipment is used in a plate bearing test?

Equipment includes hydraulic jacks to apply load, dial gauges to measure settlement, load cells to measure applied load, and a steel plate.

How is soil bearing capacity calculated from a plate load test?

By measuring the settlement of the plate under a known load, engineers can calculate the pressure applied to the soil and determine its bearing capacity.

What are the different methods of soil bearing capacity testing?

Methods include plate load tests, cone penetration tests (CPT), and standard penetration tests (SPT), each providing unique insights into soil properties.

What are the types of bearing tests other than plate load tests?

Other types include the California Bearing Ratio (CBR) test, which evaluates soil strength under standardized conditions, and cone penetration tests.

What’s the difference between CBR and plate bearing tests?

While plate bearing tests directly measure soil bearing capacity, CBR tests assess the strength of a soil sample under specific conditions.

What size plate is used in a plate load test?

Plate sizes vary but typically range from 300 mm to 750 mm in diameter, depending on factors like soil bearing capacity and structure size.

What’s the maximum size of plate used in a plate load test?

The maximum size depends on the testing area and equipment capacity, with larger plates used for testing larger areas or soils with higher bearing capacities.